When designing and building heavy equipment, the materials you use matter significantly. While steel is…

4140 Steel Properties: Understanding and Meeting Your Project Requirements

When you need to order steel for a project, there are any number of factors that you need to consider. These can include strength, flexibility, durability, resistance to corrosion, and many other aspects. To meet these needs, the steel industry has made a wide range of adaptations to steel formulations, often numbering them using a standard that makes it easier for the average metalworker to understand the aspects of what they’re working with. Today we will be discussing 4140 alloy steel properties and common applications.

What is 4140 Steel? Factors to Consider

As a medium-carbon chromium-molybdenum steel alloy, 4140 steel features the following chemical profile as a percentage of the overall weight, with the remaining balance of the steel being iron:

- Carbon: 0.38-0.43

- Manganese: 0.75-1.0

- Silicon: 0.15-0.35

- Phosphorous: 0.035 maximum

- Sulfur: 0.040 maximum

- Chromium: 0.8-1.1

- Molybdenum: 0.15-0.25

These compounds make the steel have a superior resistance to metal fatigue, as well as improved torsion strength, impact resistance, and overall toughness.

Common Applications for 4140 Steel

Overall, 4140 is a tougher steel than mild steel, providing a great steel for many projects without having to step up to more expensive options such as stainless. It’s considered a low-alloy steel, but the alloys that are used improves its corrosion resistance and strength while remaining a well-rounded steel that can deliver easy machining capabilities, high stress, and tough wear. But what industries and applications is it most commonly used in?

Overall, 4140 is a tougher steel than mild steel, providing a great steel for many projects without having to step up to more expensive options such as stainless. It’s considered a low-alloy steel, but the alloys that are used improves its corrosion resistance and strength while remaining a well-rounded steel that can deliver easy machining capabilities, high stress, and tough wear. But what industries and applications is it most commonly used in?

- Petroleum drilling: For gas and oil drill pipes, stabilizers, drill collars, and other equipment used in petroleum drilling and completion, the toughness and high strength of this steel is second to none in tough rig environments.

- Automotive parts: High-stress parts in cars, trucks, and other vehicles are often created from 4140 steel, such as shafts, gears, and pinions. The high stress and severe loads of these parts are well-suited to the toughness and strength of 4140.

- Heavy equipment: Items on construction and mining equipment that are expected to take a lot of wear and tear in the field are typically made of 4140 steel. This includes excavator teeth, crane booms, conveyors, crushers, and bulldozer blades.

- Aerospace parts: Though aluminum is more often linked to aerospace, 4140 steel is key for high-stress components such as landing gear, engine parts, and a plane’s overall structural strength.

- Defense: When heavy resistance to stress and general overall toughness is needed in the defense industry, 4140 steel fits the bill. That’s why it’s commonly used in rifle barrels, armor plating, and other high-stress components.

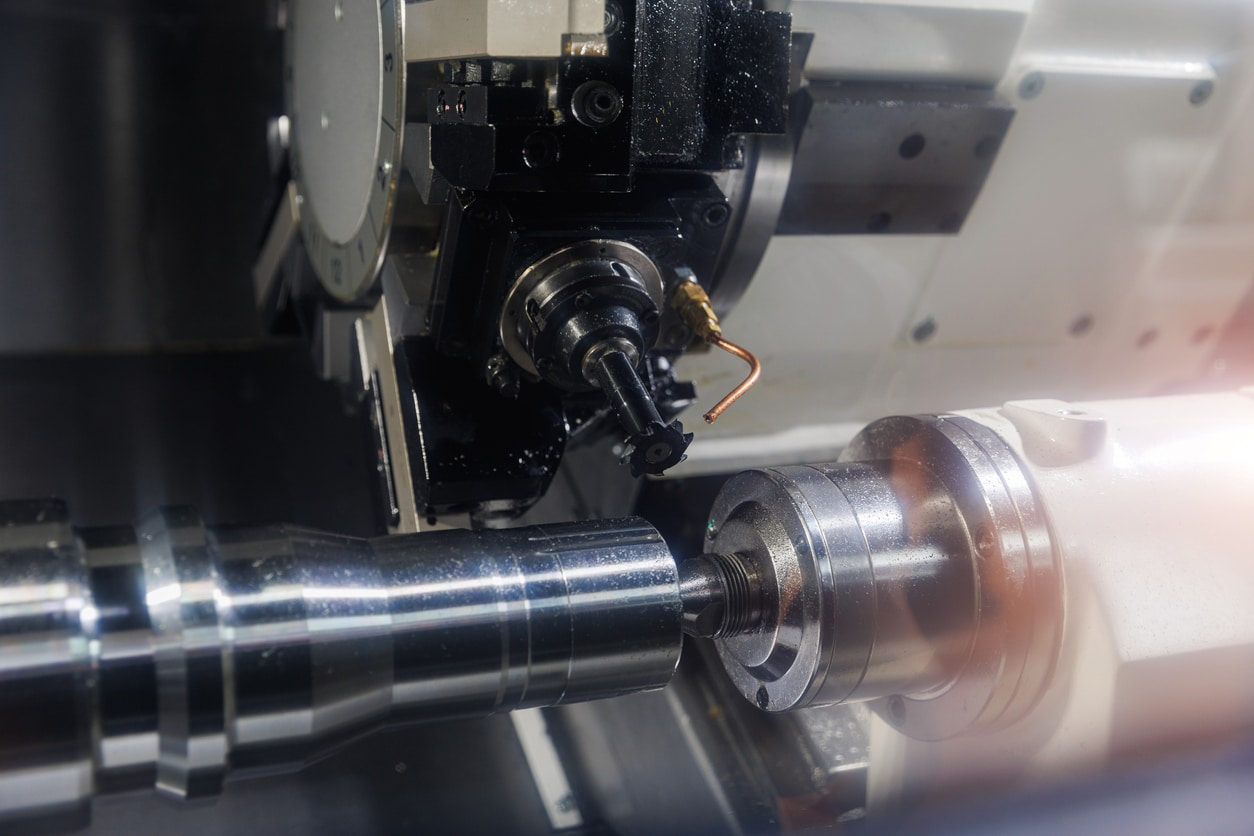

- Machine parts: Much as with automotive, spindles, lead screws, and feed screws in machines are often made of 4140 steel, due to its high degree of hardness, overall strength and resistance to stress.

- Farming equipment: When farmers work the ground, their equipment goes through a lot of wear and tear. This is why you’ll find 4140 steel in cultivator teeth, disc blades, and plow shares, due to its high resistance to wear and abrasion.

Hot Rolled, Heat Treated, and Cold Finished: What’s the Difference?

There are a lot of other terms that are often thrown around with regards to how 4140 and other types of steel are treated during processing, including hot rolled, heat treated, and cold finished. Generally speaking, these different aspects will impact the tensile strength and ductility of the steel. Here’s a quick overview of each type to help you select the right finish for your project.

Hot Rolled 4140 and 4150 Steel

Hot rolled 4140 steel has a hardness of 269/341 BHN and a hot roll finish, which means that it’s been formed at temperatures of around 1,700 degrees Fahrenheit. This relieves all of the stresses that can form at cooler rolling temperatures, and reorganizes the grain structure, making it easier to work with. It will typically have a scaled surface, some slight distortions, and rounding at the edges, which is fine for many applications, but may not work well for precision applications.

TG&P 4140 and 4150 Steel

Heat treated 4140 steel also has a hardness of 269/341 BHN, like hot rolled, but at Specialty Steel, also has a turned ground and polished finish. This means that it’s been quenched, tempered, and stress relieved to make it easier to work, then straightened, turned, and polished to provide a superior external finish. This gives the steel a polished finish that is better suited to more precise applications where shafting is required.

Cold Finished 4140 Steel

Cold finished 4140 steel has a hardness of 180/235 BHN and a cold drawn finish, which means that it’s more ductile and therefore can be more suitable for machining depending on the requirement. Cold drawn 4140 steel is pulled through dies to create a more precise dimension of steel while improving its potential hardenability and tensile strength. This makes cold finished 4140 steel a great option for high-strength performance requirements.

Specialty Steel Offers Custom Solutions for Diverse Industrial Needs

As you can see, there are some great uses for 4140 steel, and the different finishes provide you with a range of options in terms of strength and ductility. If you’re ready to make a purchase or if you still have questions about which steel would be best for your project, the experienced professionals at Specialty Steel are always happy to help. Please feel free to reach out today with any questions or concerns!