When you need metal for manufacturing, it’s imperative to know exactly what type of metal…

How Abrasion-Resistant Steel Extends the Life of Heavy Equipment

When designing and building heavy equipment, the materials you use matter significantly. While steel is one of the strongest metals available, not all types of steel are made equally. Alloy steel and abrasion-resistant (AR) steel are often the materials of choice for heavy-duty industrial products, thanks to their durability, resilience, and versatility.

But how can you know what kind of abrasion-resistant resistant steel will work best? Here’s everything you need to know about how AR steel works and how it can extend the life of heavy equipment.

What is Abrasion-Resistant Steel?

As the name suggests, AR steel is designed to withstand excessive wear and tear. During the production process, manufacturers add carbon and other alloys to increase the durability and hardness of the steel.

But there’s a trade-off. Adding more carbon makes the metal tougher and more resistant to cracks and abrasions, but it also makes the steel weaker overall. So, AR steel is not well-suited for construction purposes where it will be used for load-bearing and support.

Abrasion-resistant steel comes in a few varieties based on the carbon and alloy content. Two of the most common types of AR steel include AR400 and AR500. Another option is 4140 steel, which contains more alloys and other elements to make it harder and more wear-resistant.

Here’s a quick breakdown of the specs of each AR steel type.

- Hardness Range – 400 to 440 BHN

- Tensile Strength – 180,000 PSI

- Yield Strength – 140,000 PSI

- Carbon Equivalency – 0.47 percent

- Hardness Range – 475 to 535 BHN

- Tensile Strength – 255,000 PSI

- Yield Strength – 200,000 PSI

- Carbon Equivalency – 0.54 percent

- Hardness Range – 197 to 237 BHN

- Tensile Strength – 131,000 PSI

- Yield Strength – 95,000 PSI

- Carbon Equivalency – 0.38 to 0.43 percent

As you can see, the different variations offer better hardness and tensile strength, depending on how much carbon and alloys are added to the mix. In addition to choosing AR steel based on these properties, you can also pick the right thickness and sheet size to meet your needs.

Specialty Steel offers multiple size and thickness options for your convenience to reduce the amount of machining needed. Our customer service agents can also help you determine the best size based on what you’re trying to do with this steel.

Benefits of Abrasion-Resistant Steel

The primary advantage of using abrasion-resistant steel for your applications is that it can take much more wear and tear than standard steel plates. However, when you break down the hardness and resilience of this steel, you’ll see that there are a few other secondary advantages, like:

Thinner Gauges=Heavier Payloads

One thing that sets abrasion-resistant steel apart is that it is “through-hardened.” This means the entire metal sheet has the same hardness and wear resistance, not just the surface. As a result, you can use thinner gauges when using this steel for heavy machinery and other industrial applications.

But why do thin gauges matter? Well, the less steel you have to use for the machinery, the more space and weight you can use for hauling, lifting, and transporting. For example, if you use AR steel for dump trucks and other earth-moving equipment, you can hold more dirt and debris because the buckets are thinner. On average, you can increase the load capacity by about 10 to 20 percent by making the switch.

Long-Lasting Machinery

Heavy-duty industrial equipment is expensive to build and maintain. However, by investing in higher-quality materials during the construction process, you can save a lot more over the long term. AR steel doesn’t need as much care and upkeep as traditional steel, meaning you don’t have to pay for as many repair visits or replacement parts.

On average, abrasion-resistant steel can last up to four times as long as traditional steel, depending on the application.

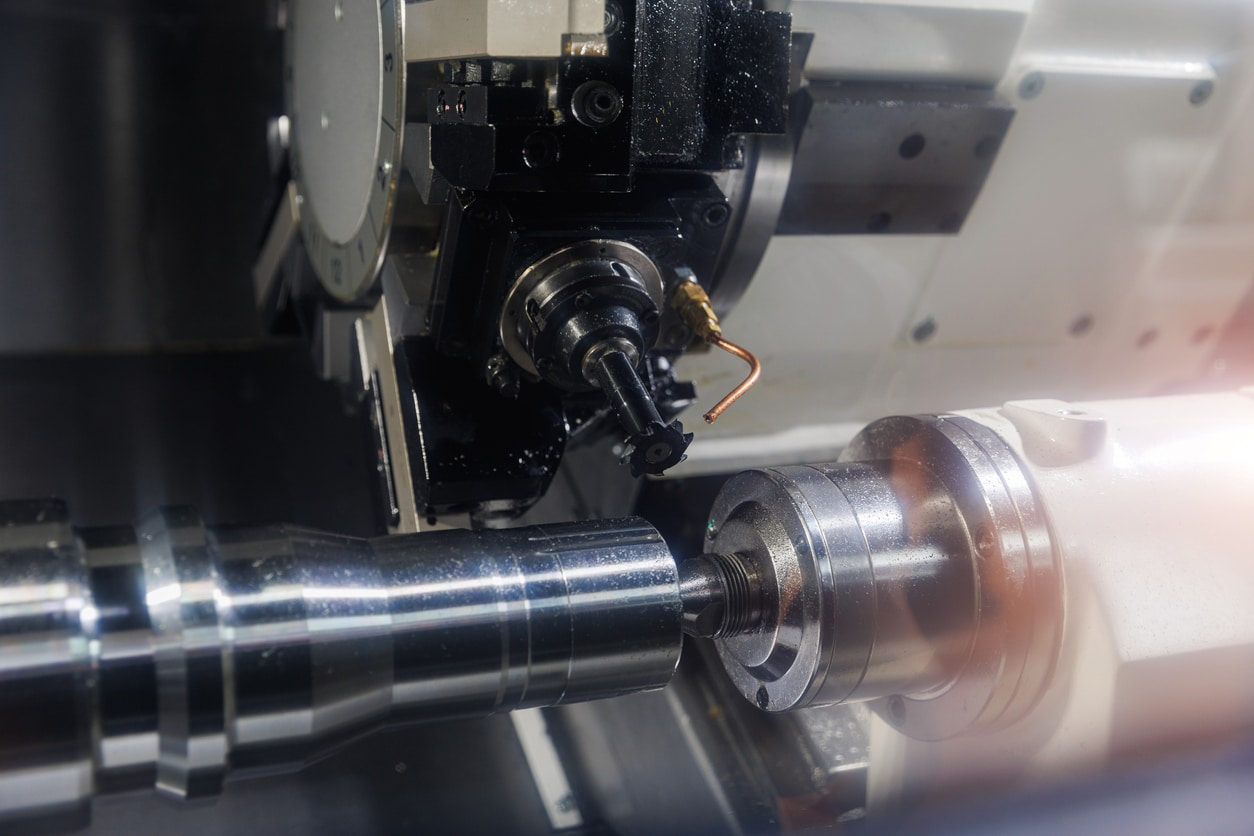

Easier Machining

Building industrial equipment requires the right tools and know-how. Low-quality steel can bend, crack, and warp under pressure during the machining process. Abrasion-resistant steel is much tougher and retains its shape and hardness from start to finish.

Overall, machining is much faster and produces more consistent results, saving you time and money. Those savings can be passed onto your clients, giving you a more competitive edge in the marketplace.

Applications of Abrasion-Resistant Steel

AR steel works best in situations and environments where wear and tear are common issues. The main industries that rely on this steel include:

- Agricultural

- Construction

- Mining

However, the type of AR steel can affect how you use it. Let’s break down the best use cases for all three types of abrasion-resistant steel offered by Specialty Steel.

AR400 Steel

This material is relatively easy to machine because it’s not quite as tough as AR500. So, you’re able to machine smaller, more precise parts without losing much hardness or wear resistance. This metal is also notable because it includes chromium, making it much more rust-resistant and perfect for outdoor applications.

AR400 steel is best used for equipment liners, construction tools, mining equipment, and construction machinery.

AR500 Steel

Because this steel is harder and tougher than AR400, it’s not as malleable or machineable. So, you can’t get as much precision during the machining process, but you wind up with a tougher, longer-lasting piece. Some common applications that use AR500 steel include armor plating, quarry equipment, cutting edges on heavy machinery, and truck plows.

4140 Steel

Since 4140 steel is the “weakest” of the three AR steel varieties, it’s not well-suited for heavy-duty industrial applications. Instead, it’s better for applications where precision and complex machinery are involved. Some common uses for 4140 steel include automotive machinery, manufacturing equipment, and tooling components.

Let Specialty Steel Provide for Your Business

When you need the best materials for your project, you can’t afford to depend on a subpar supplier. Specialty Steel prides itself on a commitment to customer service and quality materials.

We offer traceability and quality assurance on all of our AR steel plates, and our customer service team is more than happy to work with you to satisfy both your project needs and budget. Contact us today to find out more about how abrasion-resistant steel can help your business.