When designing and building heavy equipment, the materials you use matter significantly. While steel is…

Finding the Right Metric Steel Supplier: Costs, Processing, and Lead Time

When it comes to manufacturing, the supply chain can make or break your business. Because you rely on raw materials to produce your products or components, you must work with the best suppliers and vendors possible to ensure smooth and consistent results. If you’re in the market for a metric steel supplier, you may be wondering how to compare different companies to get the best results for your needs. With so many options available, the process can get overwhelming.

Thankfully, comparing metric steel suppliers doesn’t have to require trial and error on your part. Instead, you can look at various metrics and determine the best choice based on them. We’ve compiled a list of those metrics for your convenience. Here’s everything you need to know about finding the right metric steel supplier.

How to Compare Different Metric Steel Suppliers

Low Costs and Service Quality

For most companies, the bottom line is everything. So, saving money with more cost-effective suppliers seems like a smart idea from an accounting perspective. However, if you go with a “cheap” vendor, you’ll wind up paying a lot more in the long run.

For most companies, the bottom line is everything. So, saving money with more cost-effective suppliers seems like a smart idea from an accounting perspective. However, if you go with a “cheap” vendor, you’ll wind up paying a lot more in the long run.

Some of the dangers of inexpensive and unknown suppliers can include:

- Inconsistent Results – Low-cost vendors typically source raw materials from various subcontractors with little oversight or quality control. So, one batch may be top-tier, while another may be virtually unusable.

- Longer Lead Times – The more contractors and subcontractors within the supply chain, the longer it takes to get raw materials sized and machined to fit your needs. With cheaper vendors, you may have to wait longer for each shipment, slowing your business in the process.

- Dissatisfied Clients – Steel components are essential for many projects, and cheap steel can create subpar results. Your clients will notice the lack of quality and may search elsewhere for machined steel parts and products.

Overall, while low costs may be effective, you must make sure you’re not sacrificing any other elements. Instead, look for metric steel suppliers that have competitive rates and robust quality control measures in place.

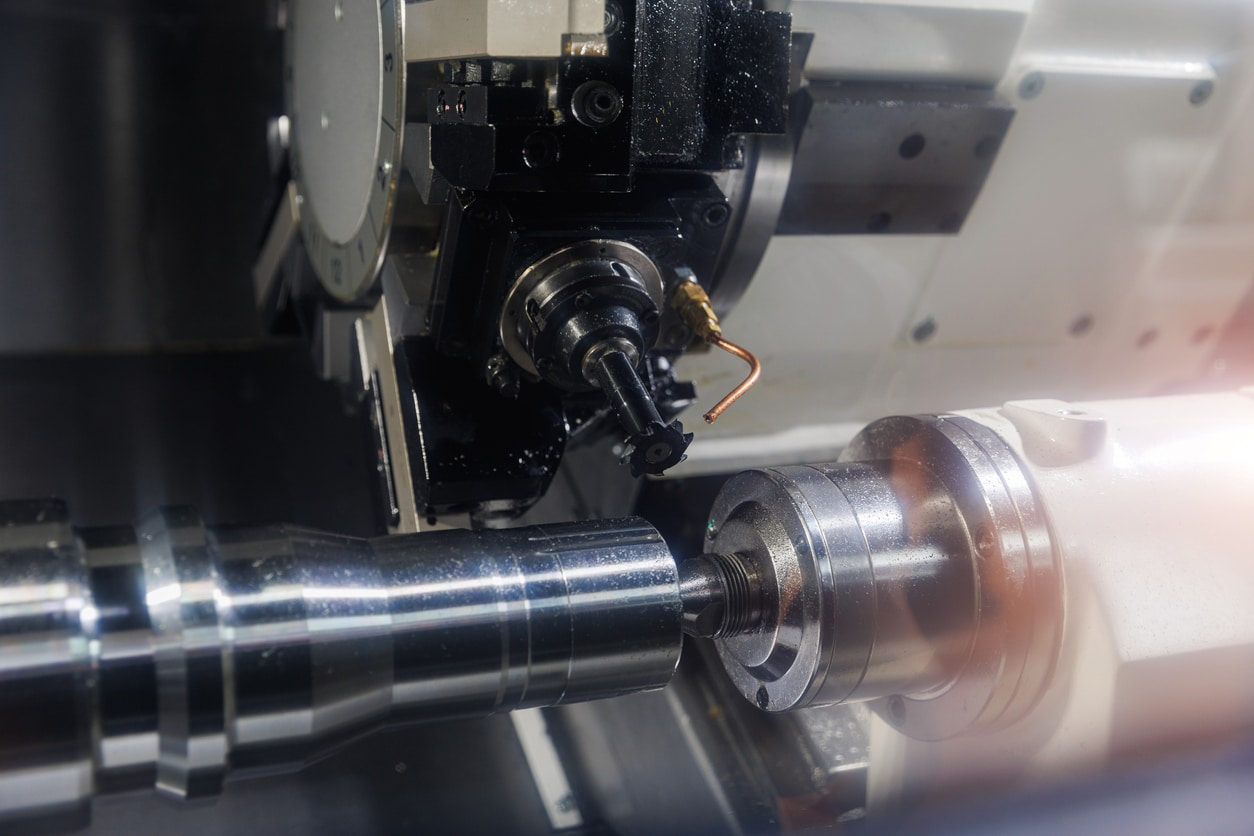

Processing

One of the main advantages of getting pre-sized metric stock is that you don’t have to do as much machining to deliver the final product. That said, you want a metric steel supplier that offers consistently high-quality stock that can work for all your needs. The better the vendor’s processing of the metal, the less work you have to do to make it usable.

An excellent way to determine whether a supplier is right for your business is whether it offers customizable stock options. This way, you can get the sizes that work best for your company rather than having to resize and potentially waste raw material. Suppliers that work with you help save your business time and money, making them even more valuable to your bottom line.

Lead Time

Regardless of the industry or business model, speed is always a critical factor. While you never want to rush a project, you need to work as efficiently as possible to ensure maximum profitability. However, as with costs, you don’t necessarily want to use a supplier with the shortest lead time. In many cases, the supplier may cut corners and deliver inferior steel, forcing you to cover for those mistakes or wait for a new shipment.

Overall, what matters most is consistency. Even if a supplier has a slightly longer lead time, they may be better for your business than a supplier that changes the lead time based on external variables. You want to work with a vendor who can deliver shipments on time every time, even if you’re scaling your business to meet increased demand.

Brand Reputation

No matter what kind of supplier or vendor you work with, it’s always best to use a company that’s willing to put its brand on the line with each order. Reputable businesses can offer references and testimonials from previous satisfied clients. That said, you shouldn’t take these references at face value. If possible, contact previous or existing clients to verify their satisfaction with the supplier. You can also ask questions from a client perspective to get a better idea of what to expect if you sign with a particular brand.

Scalability

Ideally, your metric steel needs today may be much different tomorrow. As your business grows, your supplier should be able to keep up with demand. Otherwise, you’ll be back at square one and have to compare different companies all over again. When communicating with each supplier, ask about order sizes and how other elements like costs, lead times, and processing are affected.

This way, you can be sure that the vendor is a suitable option now and into the future. Realistically, you want partners that can help you grow, not ones that will inevitably hold you back because they can’t keep up.

Specialty Steel is the Right Metric Steel Supplier For You

Specialty Steel has over four decades of experience and expertise in the steel industry. We offer a wide selection of pre-sized metric stock to meet different needs, and we pride ourselves on providing consistent, traceable results on each shipment. We specialize in high-strength alloys, meaning we can work with all kinds of industrial and commercial brands. When you need reliable steel, Specialty Steel has you covered.

We also pride ourselves on taking a customer-centric approach. We’re all about building partnerships and relationships. We can help you determine the best products for your needs and develop a schedule and budget that works for your business. Plus, as your company grows, we can scale production to meet demand.

If you’re ready to take your manufacturing to the next level, call Specialty Steel today. We have the materials, service, and reliability you deserve.