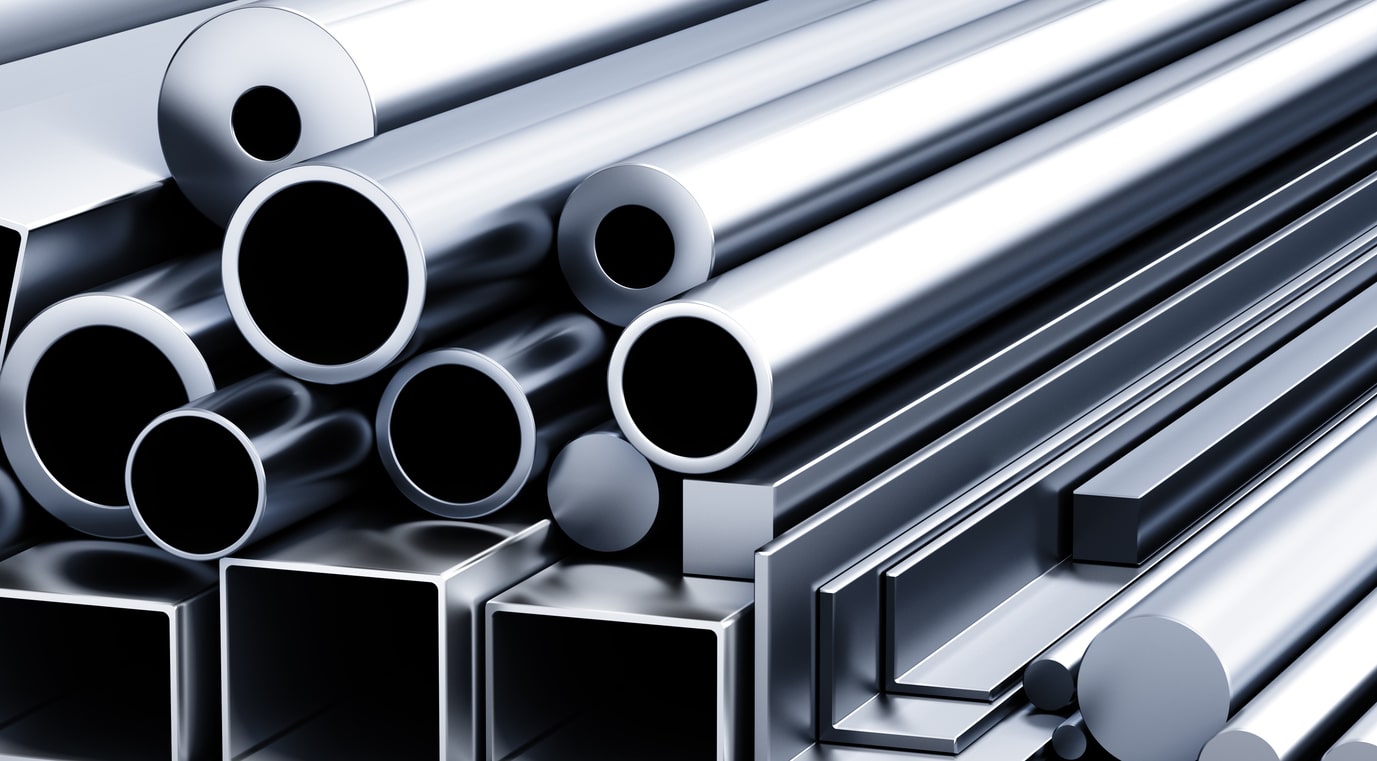

When designing and building heavy equipment, the materials you use matter significantly. While steel is…

Induction Hardened Chrome Bars vs. Chrome Plated Rods: Which is Best?

When you need metal for manufacturing, it’s imperative to know exactly what type of metal will work best for your application. In many cases, there may be multiple options that can work, but each variation has different pros and cons that you must factor into your buying decision.

Chrome shafting is often used for hydraulics and pneumatic systems because of its abrasion and rust resistance. However, you may have to make a choice: induction-hardened chrome bars or chrome-plated rods?

While both of these products are similar, they’re not interchangeable. So, let’s break down the specific details of each option and when they’re best for your needs.

What are Induction-Hardened Chrome Bars?

Induction is the process of using electromagnetism to heat and treat various metals. For induction-hardened chrome bars, steel bars are heated to transform the surface and make it much harder than normal. Once the induction process is finished, the bars are quenched and then chrome-plated.

Overall, this process results in a much stronger and more wear-resistant product. Because induction changes the microstructure of the material, it’s much tougher than regular steel.

What are Chrome-Plated Rods?

Standard chrome-plated rods are steel rods that have a layer of chromium added to the surface. Chromium is naturally hard and wear-resistant, so adding it to the steel surface makes the piece much more resilient.

This is why chrome-plated rods are used so frequently in hydraulics and pneumatics. Regular carbon steel would wear down with repeated use, but chrome retains its strength and hardness for much longer, especially when exposed to corrosive chemicals and synthetic agents.

Where Induction-Hardened Chrome Bars are Commonly Used

Overall, the best time to use induction-hardened chrome bars is when they’ll be used in heavy-duty applications or harsh environments. Some examples can include:

- Mobile Equipment – Machinery that is used in the field (e.g., mining, agriculture, or construction) should have induction-hardened bars because they’ll be exposed to debris and other elements, along with variable temperature changes.

- High-Volume Industrial Automation – When building robotics or hydraulic equipment for manufacturing, you’ll want induction-hardened rods for high-output devices. Because these rods are more precise and have better wear resistance, they can last longer, even under extreme stress.

- Marine Equipment – Machinery that’s exposed to marine environments is more susceptible to corrosion and rust. Induction hardening helps protect the core strength of the metal, ensuring fewer repairs and less costly maintenance.

Overall, when you need top-tier materials for a project, induction-hardened chrome is the superior choice. While you may have to pay more upfront, you’ll worry less about wear and tear, reducing the total cost of maintenance and upkeep.

Where Chrome-Plated Rods are Commonly Used

Standard chrome-plated rods are much better than traditional steel for hydraulic and pneumatic systems. These rods are also aesthetically pleasing, thanks to their brilliance and shine. Here are some situations where it’s better to use standard chrome rods instead of induction-hardened ones:

Standard chrome-plated rods are much better than traditional steel for hydraulic and pneumatic systems. These rods are also aesthetically pleasing, thanks to their brilliance and shine. Here are some situations where it’s better to use standard chrome rods instead of induction-hardened ones:

- Automotive – Many cars and trucks use chrome-plated rods for pistons and other engine parts. Because vehicles don’t create as much wear and tear as industrial equipment, there’s no reason to invest in high-end induction-hardened materials. Plus, some vehicles may show off the chrome rods for better visuals.

- Low-Volume Industrial Automation – Many robotics and automated systems rely on hydraulics or pneumatics to operate. If you’re creating machinery that won’t be exposed to harsh elements or used in high-volume operations, standard chrome-plated rods are more than sufficient.

- Aerospace Construction – As with cars and trucks, planes can benefit from using chrome-plated rods. Since these rods are often installed in the vehicle’s interior, they’re not exposed to extreme temperature fluctuations or environmental corrosion.

- Medical Equipment – Chrome-plated rods are perfect for medical devices and equipment because they last a long time and are naturally antimicrobial.

Overall, standard chrome-plated rods are best for situations where they’ll be used inside or within a vehicle. As long as the rods don’t undergo extreme stress or heavy-duty use, they should hold up well over time.

One thing to keep in mind is that it’s never a good idea to switch to standard chrome rods to save on material costs. If you’re using rods for heavy-duty industrial applications, weaker materials can lead to dangerous accidents and expensive repair jobs.

Comparing Both Options

As you can see, the primary difference between these two products is the induction process. However, because induction has such a profound effect on the material, the results are noticeable. Here’s a quick breakdown of how both options hold up in different situations.

Durability and Hardness

Typically, chrome-plated rods have a hardness of around RC 45-50. Induction-hardened chrome bars have a hardness of RC 55-60.

Versatility

Both pieces are primarily used in hydraulics and pneumatics. However, induction-hardened bars are much more versatile because they can be used in heavy-duty equipment, especially if that equipment will be used in hazardous or rough environments.

Cost

Because of the induction process, hardened chrome bars are more expensive than regular chrome-plated rods. While you get a much more durable product, the price tag can often be a deciding factor when determining which piece to use in a particular project.

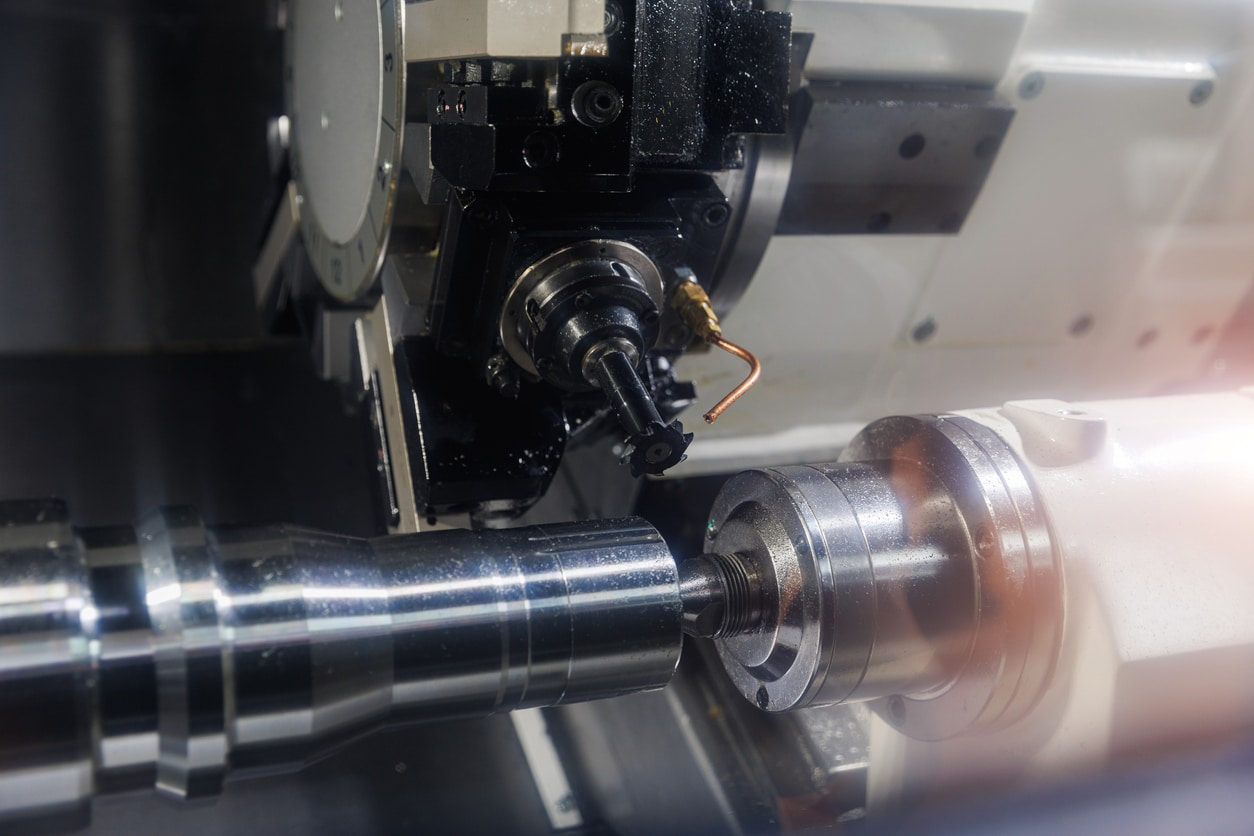

Machinability: Chrome bars are machinable. Once the outer layer of chrome is removed, you are left with a machinable core material, beneficial for situations that require end-machining or threading.e

The Final Verdict: Specialty Steel Has You Covered

No matter what kind of chrome bars you need, Specialty Steel has both options in stock. We can work with you to provide high-quality chrome-plated rods or induction-hardened bars in the size and diameter necessary for your project.

What makes Specialty Steel unique is that we pride ourselves on sourcing our materials from high-quality suppliers. We’re committed to traceability with each order so you can feel confident that you’re getting the best metal possible. We’re also customer-focused, so we work with you to ensure each order matches your needs and your budget. Contact us today and see what we have in stock.