In construction, steel plates and rods are essential for numerous projects and structures. However, while…

How Chrome Plated Shafts Improve Equipment Longevity

When ordering metal for heavy-duty equipment, you must make sure you get the right material for the job. While most metals are durable and wear-resistant, they’re not all made the same. For example, when it comes to hydraulic and pneumatic systems, chrome-plated shafts are typically the best option.

But what makes heavy-duty chrome shafting so vital for these operations? Well, there are quite a few features that make these shafts worthwhile, so let’s break them down.

What are Chrome-Plated Shafts?

When discussing chrome shafting, there are two unique options you can choose from:

When discussing chrome shafting, there are two unique options you can choose from:

- Chrome Plating Only – These rods use standard plating techniques to add a layer of chrome to a steel base.

- Induction-Hardened Chrome Plating (IHCP) – Rather than using external heat sources, induction heating turns the metal itself into a heat source. This process superheats the steel during plating, creating a much harder surface.

At Specialty Steel, we offer both options. If you’re unsure which one you need for your next project, our sales team can help you compare different products. While each chrome shaft offers similar features, slight variations can make them work best in unique situations and projects.

How Chrome-Plated Shafts Improve Equipment Longevity

Reduced Friction

One of the main advantages of using chrome plating is that it has a remarkably low coefficient of friction. Because the chrome creates a smoother surface, it’s not abrasive and won’t generate as much heat when rubbed against other parts.

While it’s still necessary to use oil or other lubricants to reduce friction further, chrome-plated shafts are the best option compared to other types of metal. A chrome rod can be used for repetitive movement within various mechanical systems, and it won’t break down.

Increased Durability

The impact resistance of induction-heated chrome-plated rods is around Rc 45-50. If you use chrome-plated only rods, the hardness increases to 55-60. The yield strength of standard plated rods is around 110,000 PSI.

Because of chrome-plated shaft durability and hardness, it can withstand impacts and wear and tear better than other metals. This is why chrome-plated shafts are commonly used in hydraulic and pneumatic systems where pressure and the risk of onsite impacts are high.

Easier Cleaning and Maintenance

Chrome is naturally rust, mold, and bacteria-resistant. These shafts can be deployed in industrial and commercial settings, including those with high humidity levels or exposure to salt water. Chrome can work well in marine settings because it won’t rust as easily as other metals.

When looking at the structure of chrome, it’s densely packed and non-porous. So, it’s much easier to clean and restore, even when talking about chemicals and other synthetic agents. When cleanliness is critical (i.e., in medical or healthcare settings), chrome is the gold standard.

Better Corrosion Resistance

Many industrial and commercial job sites are exposed to various elements that can corrode or destroy metal. For example, marine environments can cause rust and corrosion as saltwater interacts with various metal surfaces.

Chrome plating is naturally corrosion-resistant, so it can withstand the rigors of any job site. Chemicals and environmental substances won’t damage or destroy the chrome surface, which protects the steel inside.

Top Chrome-Plated Shaft Applications

Understanding the benefits of chrome plating is one thing, but seeing it in action is another. Here are some of the most common areas where chrome-plated shafts from Specialty Steel are used.

Hydraulic and Pneumatic Systems

Thanks to its friction resistance, chrome-plating shafting works perfectly for hydraulic and pneumatic systems and equipment. Even better, these shafts can be deployed in both industrial and mobile job sites. For example, agricultural and mining equipment can rely on chrome-plated rods because they’re not affected by moisture, dirt, and other environmental hazards.

Pump Shafts and Rotors

Because chrome rods are durable and heat resistant, they can work well in machinery that uses a lot of repetitive motion. Rotors and pump shafts need to work consistently without overheating or melting, so chrome rods are perfect. They can withstand the rigors of the job without wearing down or breaking.

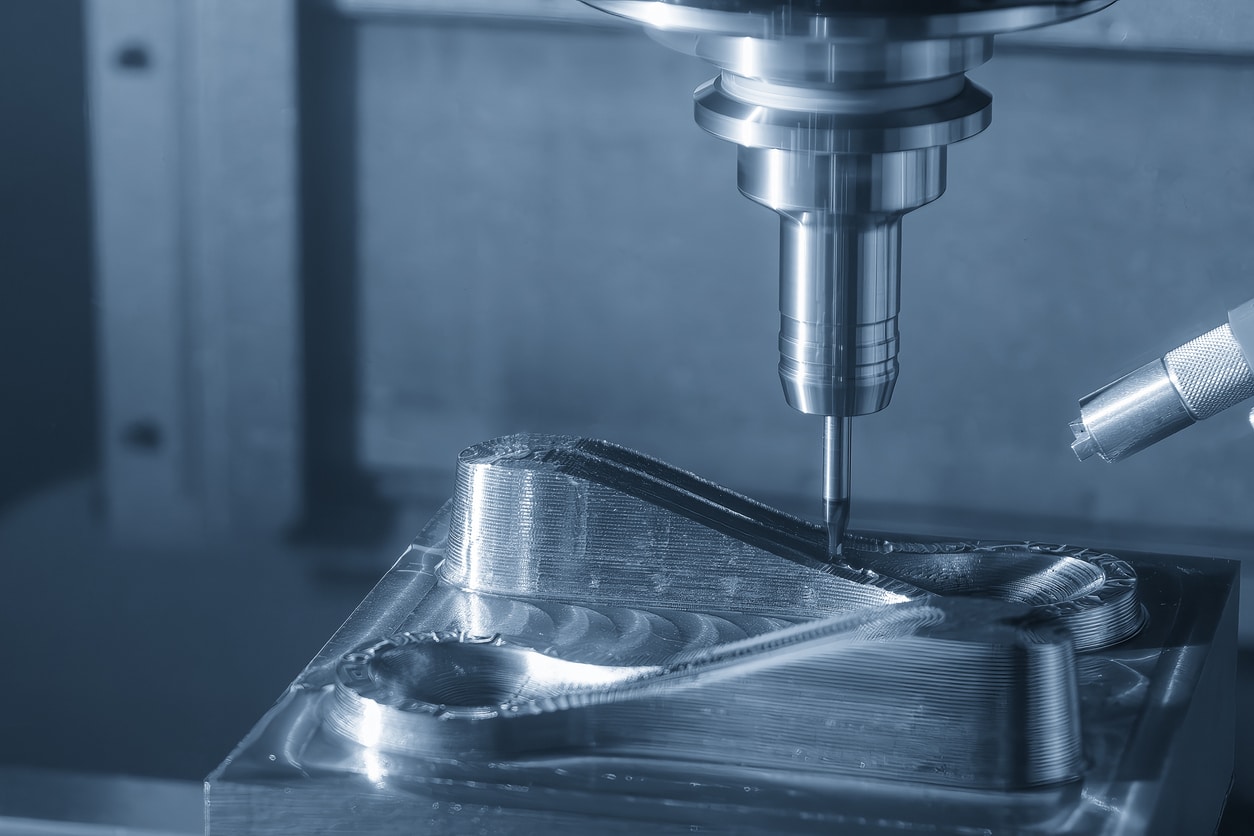

Cutting Tools

Although chrome rods are not suitable for holding a cutting edge, they can be attached to different spinning blades and cutting tools. These rods won’t overheat and they aren’t affected by dirt or debris created by the tool.

Punches and Bores

Chrome-plated steel shafts are highly impact-resistant, making them ideal for situations that require punching and boring. Chrome can absorb the vibrations and impacts of both of these operations better than most other metals. Plus, if there is any debris or blowback during the process, chrome won’t corrode or scratch easily.

Automotive

Although chrome plating is designed for practical purposes, it can also be quite decorative. When chrome is polished, it delivers a brilliant shine that captures everyone’s attention and draws their gaze.

For this reason, some cars use chrome shafting for both practicality and decoration. For example, hot rods with an exposed engine may use chrome-plated pistons and rods to make the entire vehicle look more visually striking.

Medical Equipment

Because chrome is naturally antimicrobial and easy to clean, it can be used for different medical devices and equipment. These pieces are easy to sanitize, and they won’t corrode from harsh chemicals or cleaning agents.

Get Quality Chrome-Plated Shafts From Specialty Steel

Regardless of the industry you’re in, chrome-plated shafting can yield some incredible results. At Specialty Steel, we offer custom sizes and plating options to help you stay within your budget without sacrificing on product quality.

We pride ourselves on taking a customer-first approach. When you contact us, our sales team will walk you through the selection process and make recommendations based on your needs. As a metal supplier, we offer quality assurance and traceability on all of our products, and we’re proud to work with other high-quality suppliers around the globe.