When ordering metal for heavy-duty equipment, you must make sure you get the right material…

Customizing Steel Rod and Plate Sizing for Precision and Efficiency in Construction

In construction, steel plates and rods are essential for numerous projects and structures. However, while it’s relatively easy to get standard steel plate sizes, doing so can often lead to problems and bloated costs.

Typically, standard sizes won’t fit the application which means you must cut, shape, and size the material into what you need. Unfortunately, that takes time away from the project and adds expenses for the resources.

Plus, it’s unlikely that you’ll be able to use all of the steel, even if you try to maximize its yield. So some of your investment will literally go to waste.

Instead, it’s often better to buy customized steel rod and plate sizes from a reputable supplier like Specialty Steel. By customizing your orders, you get exactly what you need every time.

The Power of Pre-Cut and Customized Steel Plate Sizes and Rod Sizes

Some prefer to buy standard-sized steel because it seems more cost-effective and efficient. However, while you may save some money upfront, you’ll often wind up wasting more in the long run. Here are four compelling reasons to buy custom:

Less Waste

No matter how good your team is at machining steel, there will always be waste left over. Sometimes, you may just have a few pounds of scraps, but other times, you may leave entire sections unused.

By buying custom thicknesses and dimensions, you don’t have to do as much machining to get the piece to fit, if at all. Not only will there be far less waste, but you also don’t have to get creative with how to maximize each sheet or rod. Plus, you don’t have to pay for expensive scrap removal.

Better Efficiency

One of the main problems with buying and machining standard-sized steel is the time required to do so. Construction has to halt while each piece is crafted, slowing the project and leading to expensive delays.

Instead, custom-cut steel is ready to go as soon as it arrives on the job site. Because each piece is machined to order, you don’t have to waste time measuring, cutting, re-measuring, and fitting them.

Because time is money, efficiency can yield substantial savings. If you plan everything right, you might complete the project under budget, making investors and management happy.

Better Precision

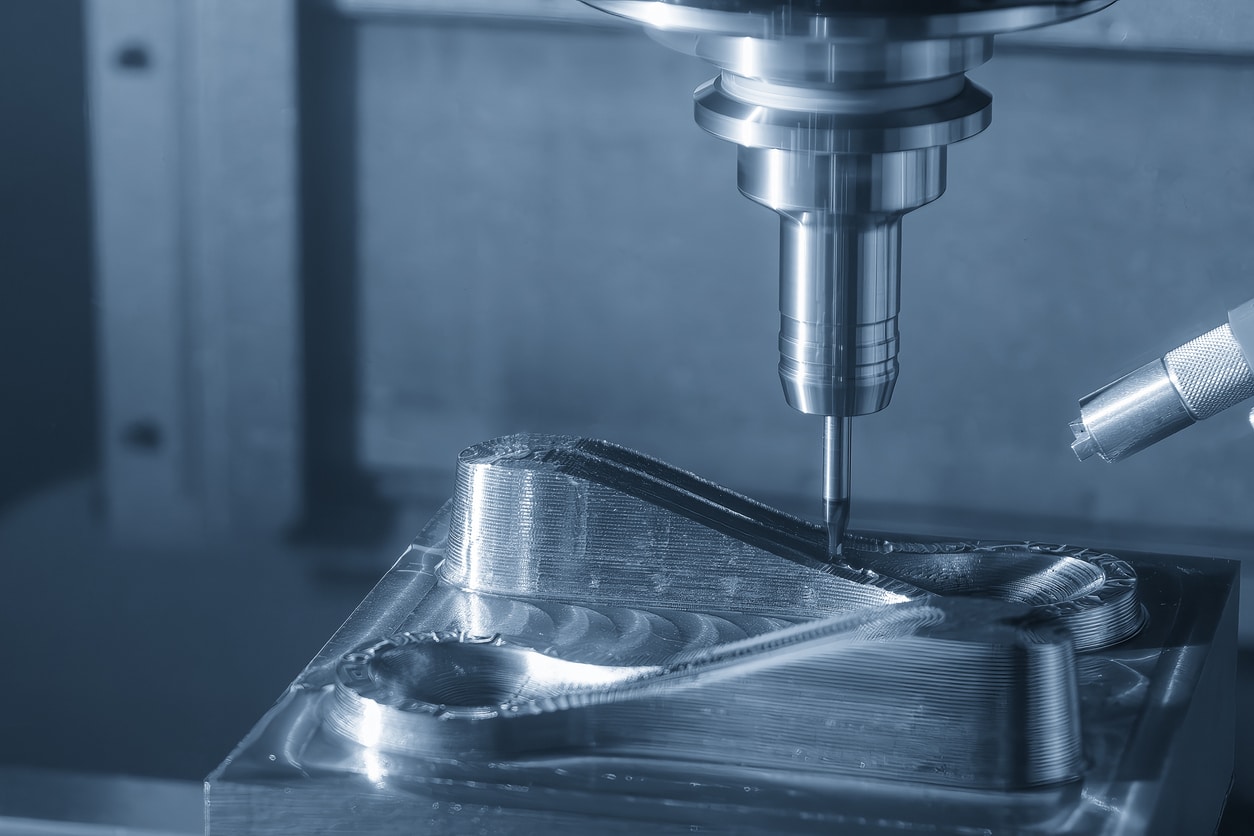

There are limits to what kind of machining you can do on site. Ideally, each piece will have to be sized and shaped in a controlled environment to ensure precise consistency. Otherwise, there will be slight variations among pieces, leading to added work and wasted time.

Customized steel plate sizes will match your exact dimensions and thicknesses. Even if you’re buying in bulk, you can be confident that the last piece will be identical to the first. With such precision and reliability, the results are much stronger overall. No more cutting corners or using a piece that’s “good enough.”

Flexibility for Complex Projects

Because of the limits of on-site machining, you may be compelled to focus on only a few types of construction methods. However, if you buy customized steel rods and plates, there are no limitations to what you can achieve. Complex projects are much easier to complete because you have the exact parts and sizes you need.

Overall, customized steel plate sizes enable you to do more and save time and money on each project. Once you start seeing the results, you’ll realize that there’s no better way to order materials for construction.

The Benefits of Using a Reliable Steel Supplier

Customized steel rods and plates are only as good as the supplier. Cheap companies don’t worry about factors like consistency and precision, meaning each batch will have slight varieties from one piece to the next.

Instead, it’s far better to work with a reputable provider like Specialty Steel. Here are some of the top reasons to buy from us.

Better Customization Results

Not all suppliers know how to machine different steel grades. While something like 4140 steel is relatively easy to machine, 4150 steel is much harder and tougher, making it more challenging to get the same results.

A reputable supplier knows how to approach each steel grade to fulfill an order. Top-tier companies also know what kind of cutting method to use (e.g., laser vs. plasma) to get the best quality possible.

So, when comparing different suppliers, ask how many similar projects they’ve done and get references if possible. This way, you ‘ll know if the company is capable of producing exactly what you need.

Quality Assurance & Traceability

High-end suppliers offer full transparency of their supply chain so you know where your steel originated and who handled it along the way to your construction site. At Specialty Steel, we offer comprehensive traceability of all of our products. This kind of quality assurance helps give you peace of mind that your custom steel plates and rods will work perfectly for the job.

Better Inventory

Reputable steel suppliers have a strong supply chain that can adapt to changes and disruptions. Also, high-end providers will already have extensive inventory on-hand for faster results. You can’t afford to wait weeks or months for raw materials to come into the warehouse, then get machined to your specifications. You need a supplier that already has the metal in-house and can customize it quickly as needed.

Let Specialty Steel Be Your Customized Steel Supplier

You know the value of getting your construction project done on time and on budget. Customized steel can help you achieve your objectives faster and more affordably than you may realize. With precise order options and impeccable quality assurance, Specialty Steel is your one-stop shop for all customized steel plate sizes. Contact us today and we can walk you through the different options available.