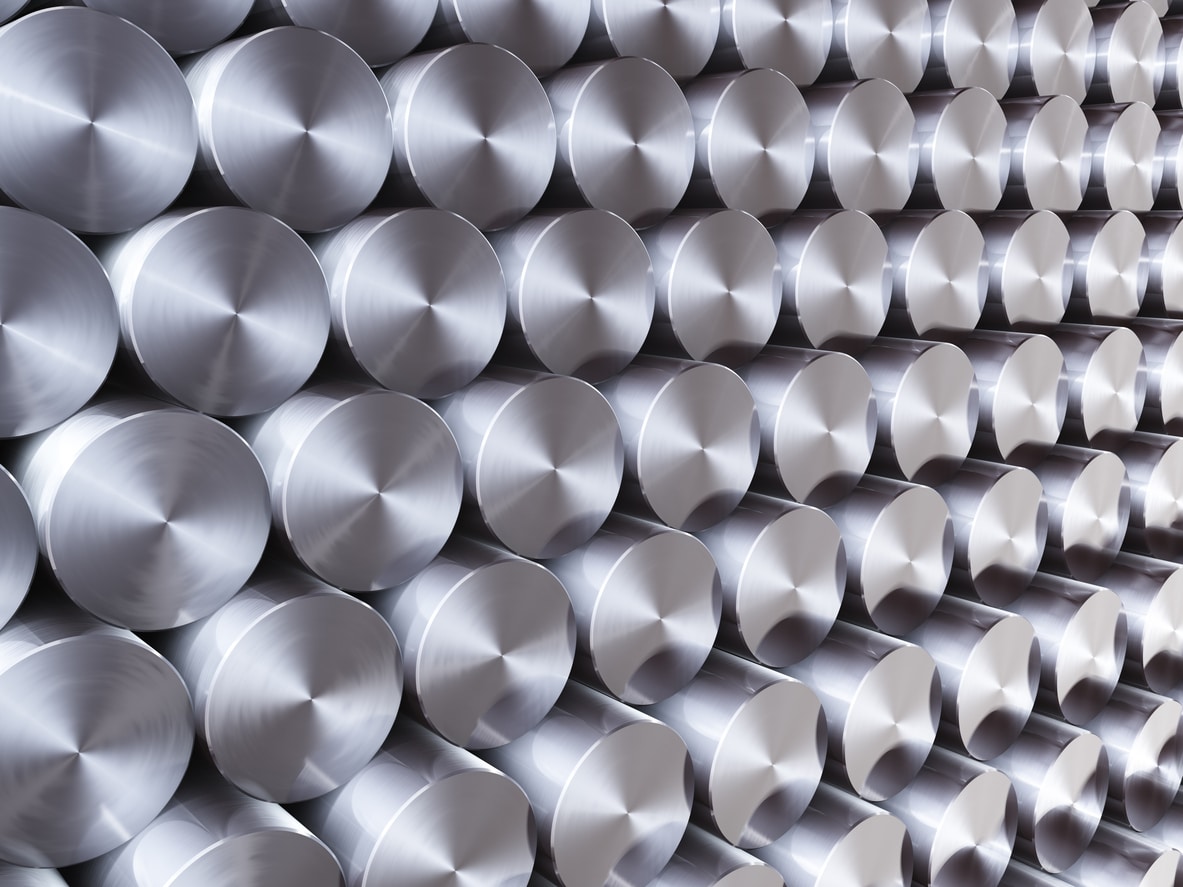

As you start sourcing metal for your next project, you know how crucial it is…

Why Choose 316 Stainless Steel? 316 Stainless Steel Properties and Benefits

Stainless steel comes in a few varieties, and 316 (and 316L) stainless steel is one of the strongest and most versatile options. This type of steel is austenitic, meaning it’s not magnetic and doesn’t harden via heat treatment. Outside of 304 stainless steel, 316 and 316L are some of the most common variations available.

What is 316 Stainless Steel? Key Composition Factors

316 stainless steel is an austenitic, non-magnetic alloy known for its exceptional corrosion resistance and strength. Its chemical composition typically includes:

- Chromium: 16-18%

- Nickel: 10-14%

- Molybdenum: 2-3%

- Carbon: Around 0.08%

For 316L stainless steel, the carbon content is reduced, making it more resistant to carbide precipitation and ideal for heavy gauge components. The steel’s face-centered cubic (FCC) crystalline structure further enhances its strength and corrosion resistance, making it a reliable choice for demanding applications.

Top Benefits of 316 Stainless Steel

There are a few unique reasons why 316 stainless steel is so widely used across multiple industries and projects. The primary advantages of this material include:

- Corrosion Resistance – Most materials will not corrode this steel, including saltwater, acids, and chemicals.

- Heat Resistance – Since 316 steel doesn’t harden with heat treatment, it’s very heat resistant. Various industries can use this steel in heavy-use environments without damaging the surface or compromising the metal’s integrity.

Durability – This steel is hard to machine because it’s so durable. This strength allows 316 stainless to work in many heavy-duty environments without buckling, bending, or breaking.

Which Industries and Applications Benefit the Most From 316 Stainless Steel?

Thanks to the attributes outlined above, both 316 and 316L stainless steel work well for multiple industries, especially those where corrosion resistance is crucial. Here’s a breakdown of the different areas where 316 steel works best:

Foodservice

316 stainless steel doesn’t attract biological matter, meaning bacteria and viruses struggle to stay alive on the surface. So, many foodservice operations use this metal for food preparation and storage. Additionally, the chemicals and acids in foods will not corrode the surface, so this material is easy to clean and maintain for years.

This steel is commonly used to make prep stations, wash sinks, coolers, freezers, and cooking equipment. Since it is heat-resistant, it can work as a cooking surface. However, due to its higher cost, most operations use other metals for grill tops. Foodservice businesses that are close to saltwater may use 316 steel because of its natural corrosion resistance to saltwater.

Marine Operations

This type of stainless steel is marine-safe, meaning it won’t corrode or rust when exposed to ocean water. So, many marine operations may use 316 steel since it will hold its shape, even if submerged in saltwater for extended periods. Warm salt water can eventually corrode this steel, but if it’s cleaned and maintained well enough, that shouldn’t be a problem. In fact, this steel can work well for offshore structures.

Chemical Plants/Refineries

Most chemicals and synthetic materials won’t corrode or damage the structural integrity of 316 stainless steel. So, many chemical plants and refineries can use this metal for equipment, storage containers, and other surfaces. Chemical dust and spills are easy to wipe off and clean, and the steel should still maintain its durability and resilience.

Medical Field

Since biological material doesn’t survive on the surface of 316 stainless, it works well for medical equipment. Stainless steel surfaces are easy to clean and keep free of bacteria and viruses. Surgical equipment can also be made from 316 steel, as it’s biocompatible and doesn’t corrode. There’s also less chance of cross-contamination when using 316 stainless steel tools.

Welding and Heavy Gauge Equipment

While you can use standard 316 stainless steel for welding, its relatively high carbon content means it’s more prone to cracking and weld decay. In these situations, it’s better to use 316L stainless, which has a lower carbon composition (0.3 instead of 0.8 percent). Otherwise, 316L is still feasible for all the industrial applications outlined above.

Buy 316 Stainless Steel From Specialty Steel

We sell dual-certified 316/316L stainless steel in 10 and 12-foot sizes, allowing you to use it for many different projects and applications.

Specialty Steel is proud to offer high-quality steel that meets ISO quality standards. We also trace each batch of steel to the source to ensure its quality and craftsmanship. Our customer service is impeccable—we value our clients and work hard to ensure your satisfaction with each purchase.

Contact Specialty Steel today to order 316 stainless. As a wholesaler, we can provide you with as much steel as you need for your next project. Contact us for a quote today!