Although steel is a reliable material, not all steel is created equally. Depending on what…

Where Corrosion Resistant Steel Excels Across Industries

Although steel is a durable and reliable metal, it must endure constant wear and tear whenever it’s deployed in the field. So, even though traditional steel seems like it can withstand practically anything, it’s prone to rusting and weakening over time, especially when exposed to the elements.

Fortunately, if you’re looking for high-quality steel for your next project, you don’t have to rely on subpar materials. Instead, you can choose corrosion-resistant 316 stainless steel from Specialty Steel. This variation is up to virtually any challenge, regardless of the industry or environmental factors.

To illustrate this point, let’s break down everything you need to know about corrosion-resistant steel, including how it’s made and when it works best.

What is Corrosion-Resistant Steel?

As the name suggests, corrosion-resistant steel is designed to withstand the elements that can cause rusting and other corrosive damage. Alloys like 316 stainless steel are highly resistant to corrosion, making them suitable for extreme environments, such as marine applications and oil and gas mining.

How is Corrosion-Resistant Steel Made?

Corrosion-resistant steel is made by adding other elements to the metal during manufacturing. Here is the breakdown of 316 stainless steel, including what each element does.

Carbon (.08 percent max)

Carbon is a primary element of steel and determines its overall hardness.

Manganese (0.2 percent max)

Manganese helps improve the hot handling capabilities of steel, as well as its strength and hardness.

Silicon (1 percent max)

Silicone helps improve the chemical resistance of steel, making it more impervious to oxidation and sulfuric acid.

Phosphorus (0.45 percent max)

Phosphorus makes the steel more machinable and doesn’t crack or bend too much.

Sulfur (0.03 percent max)

Sulfur also helps with machinability, but too much can reduce corrosion resistance.

Chromium (16 to 18 percent)

Chromium gives stainless steel its luster and is the primary component that aids in corrosion resistance.

Molybdenum (2 to 3 percent)

Molybdenum also helps improve the steel’s corrosion resistance and makes the steel retain its strength at high temperatures.

Nickel (10 to 14 percent)

Nickel helps the forming process, so everything blends well together. Nickel is also naturally corrosion resistant, making the steel stronger and more resilient.

When Should Corrosion-Resistant Steel Be Used?

As expected, corrosion-resistant steel like 316 stainless is designed to be deployed in environments where wear and tear are common. Metal corrosion typically occurs from water, oxygen, dirt, chemicals, and other debris. Steel can also break down when used against hard surfaces, like other metals or rocks.

That said, while corrosion-resistant steel is highly adaptable and useful in many situations, it’s not always the best choice for the job. Each type of steel is designed for specific purposes, so choosing the right material for your needs is crucial.

Industries That Benefit From 316 Stainless Steel

Knowing the general benefits of corrosion-resistant steel is one thing, but let’s break down the various situations where this material will excel on the job. Here are a few situations when you would want to choose 316 stainless steel from Specialty Steel.

Construction

While stainless steel isn’t necessarily ideal for load-bearing applications, it can be well-suited for decorative and accent elements during construction. For example, handrails, elevator components, and other front-facing pieces can be made with corrosion-resistant steel.

Typically, anything people touch regularly can be made with stainless steel. Germs and oils from human hands won’t corrode the material and are relatively easy to clean. Plus, polished steel looks visually striking when used in accent pieces.

Oil and Gas Mining

Industrial mining equipment must be tough enough to handle the most extreme environments on earth. Not only does this machinery have to withstand the wear and tear of the job, but it also has to resist rusting and corrosion from various chemicals and environmental elements.

Stainless steel is a good material for pistons and pneumatic systems in oil and gas equipment. Because it resists chemicals and oxidation, it will withstand the rigorous wear and tear of mining and excavation projects.

Foodservice

Although 316 stainless steel is tough enough for oil and gas mining, it’s versatile enough to work well in food service environments. Many commercial kitchens utilize stainless steel for equipment, including walk-in coolers, freezers, prep stations, and dishwashing stations.

Corrosive-resistant steel is commonplace within the food service industry because it’s easy to clean and maintains its strength and resilience for decades. Even high-volume kitchens can utilize this material without the risk of cross-contamination or rusting. Water, food, and other pathogens can be easily wiped away from the surface without damaging the structural integrity of the metal.

Medical Equipment

Stainless steel does not harbor bacteria or microbes very well, making it an ideal choice for medical-grade equipment. When surfaces must be sanitized and cleaned often, stainless steel is a primary choice for many clinics and hospitals.

It’s also important to note that corrosion-resistant steel is nonmagnetic, so it won’t interfere with highly sensitive equipment that may use magnetic fields.

Chemical Plants and Refineries

Although water and oxidation are primary causes of metallic corrosion, various chemicals can weaken the metal’s surface structure. Fortunately, stainless steel is designed to withstand most chemical spills, making it ideal for plants and refineries where these elements are commonplace.

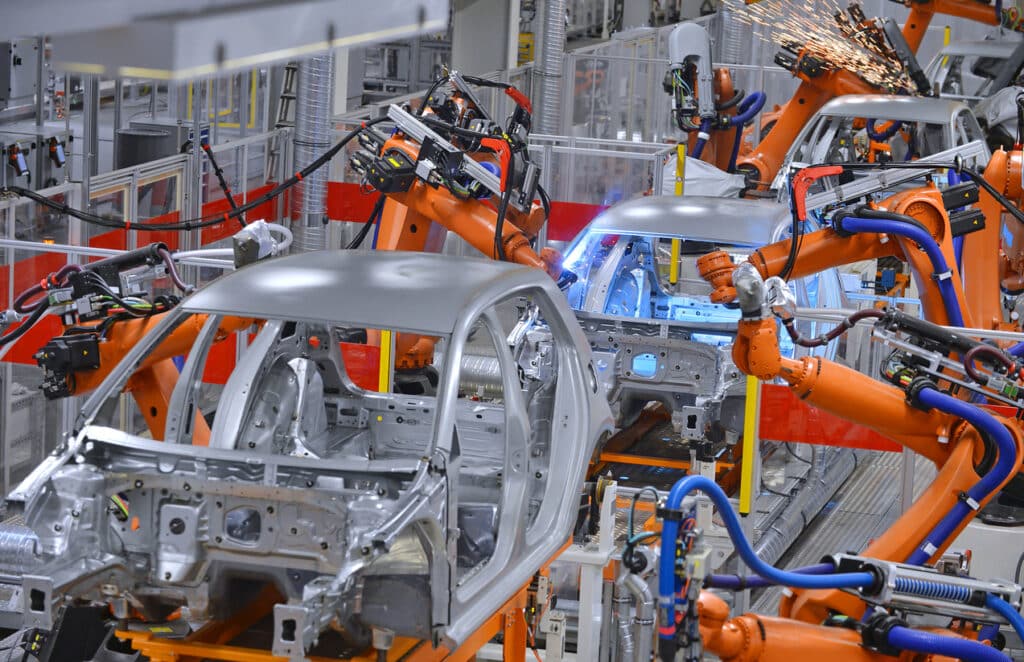

Automotive

Stainless steel components work well for hydraulic and pneumatic systems because they can withstand continuous wear and tear without overheating, cracking, bending, or breaking. Some automotive elements, such as pistons and engine block parts, are made from stainless steel. Polished stainless steel also looks fantastic for exposed engine pieces like those on vintage or retro vehicles.

Buy Your High-Quality Steel From Specialty Steel

Now that you know the value of corrosion-resistant steel, you can order as much as you need from Specialty Steel. We pride ourselves on ensuring the highest quality and traceability of our materials.

We offer 316 and 316L stainless steel in custom shapes and sizes to meet your needs. Contact us today; our customer service team can assist if you’re unsure what will work best.